DANIEL MCGOVERIN

HIGH PERFORMANCE SHORTBOARDS DESIGNED AND HAND CRAFTED IN WELLINGTON, NEW ZEALAND.

For those wanting unique surfboards tailored to your own preferences and approach. DMG Surfboards are crafted by Daniel McGoverin in Kilbirnie, located on the South Coast region of Wellington, New Zealand - walking distance to Lyall Bay beach.

From pointy nose thrusters to volume friendly swallow tails for every day conditions, at DMG Surfboards, we enjoy creating boards tailored to suit our local waves.

DANIEL MCGOVERIN, DMG SURFBOARDS

SOUTH COAST, WELLINGTON

ABOUT OUR BOARDS

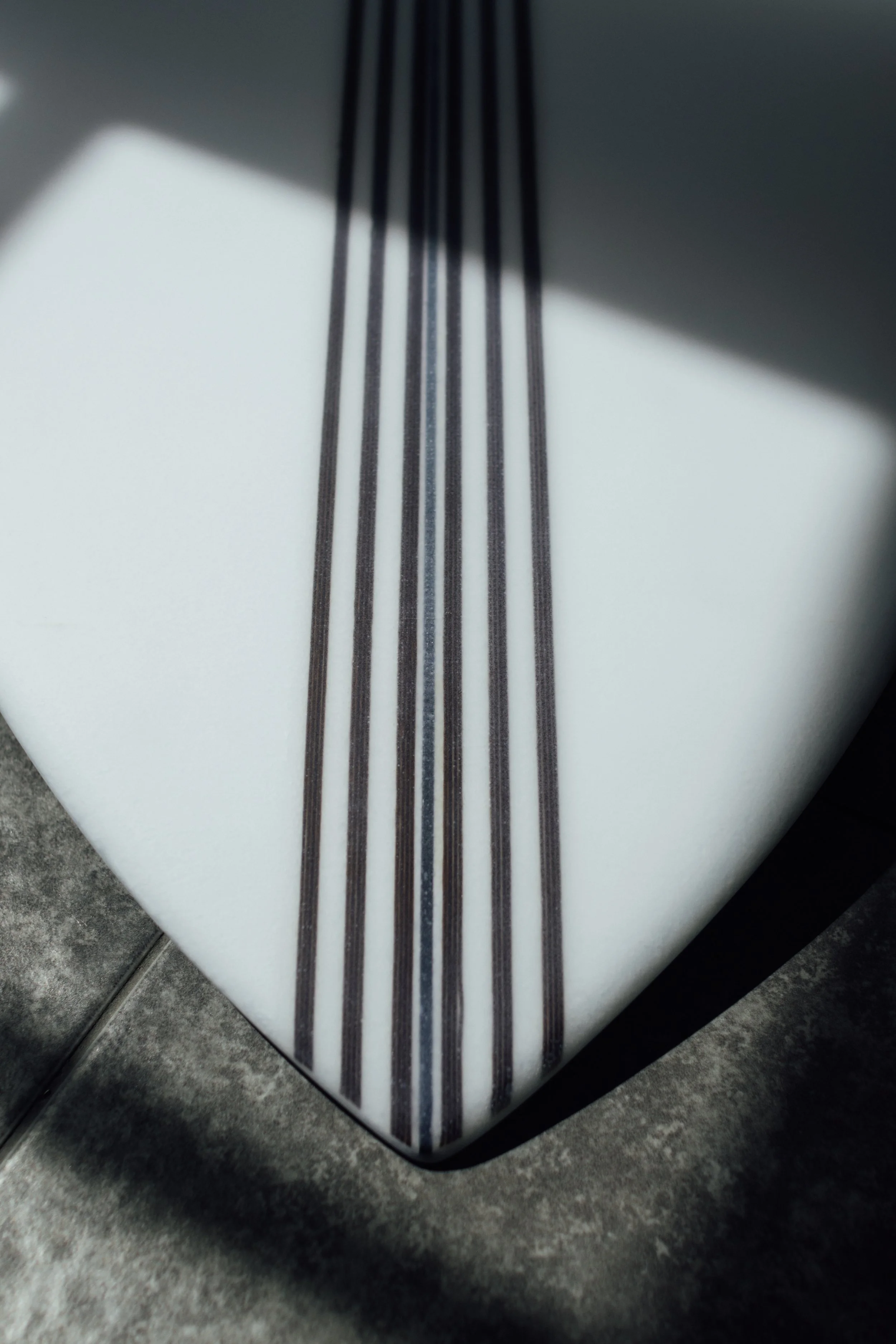

GEOFLEX TECHNOLOGY

ALL DMG SURFBOARDS USE GEOFLEX TECHNOLOGY TO AID IN BOARD STRENGTH AND PERFORMANCE. HERES THE LOW DOWN ON HOW IT WORKS:

EPS:

At the core of a DMG board is an EPS blank, these are constructed in house and use foam PVC stringers. This allows us to maintain absolute consistency throughout the entire range and deliver at an affordable price.

EPS is also a more environmentally friendly product, and in this high waste industry, that's a big plus.

FIBREGLASS/EPOXY:

All DMG boards are glassed with the highest quality fibreglass and Kinetix Epoxy resins to achieve a tough, light and great performing surfboard.

BASALT REINFORCEMENT

Basalt reinforcement is at the heart of our board construction, so heres a little explanation of what its all about. Derived from volcanic rock, Basalt is a much more environmentally friendly option compared to carbon, but being eco isn’t the end of basalts story.

Below is Sanded Australia’s very informative explanation of the benefits of Basalt: In it’s raw neat form without a matrix (resins), it is only about 12% higher in strain-to-failure than conventional e-glass. Now 12% doesn't sound that impressive, but as you know in composites, it is. Here's where it gets really cool - when you saturate it with epoxy, the strength properties grow from 12% higher than glass in strain-to-failure to 92% higher.

Most surfboard builders don't think about this, but it is really important to try to match a fiber's elongation percentage with the matrix elongation percentage

This is why Basalt should be looked at for the real functional use in surfboards that take a beating. Basalt fibre is a perfect harmonic marriage with epoxies, hence why we recommend using epoxy to get the true strengths in all our advanced composites. So when basalt and epoxy load up, they fail as a unit instead of two lower energy failures - meaning they hold in together as much as they can until they finally fail.... together. Compared to Epoxy and Carbon - two different elongations, two different Failure points.

A harmonic elongation reduces vibration - meaning, in a surfboard - less vibration, less chatter.